|

What is Vaccum casting?

|

Vacuum casting is a highly efficient and cost-effective method for producing small to medium quantities of high-quality parts. This process involves creating a silicone mold from a master pattern and then using it to cast parts under vacuum conditions. The vacuum ensures that the casting material flows evenly into the mold, eliminating air bubbles and achieving a high level of detail and surface finish. |

Why Choose Our Vacuum Casting?

High Precision and Detail: Vacuum casting allows for the production of parts with intricate details and tight tolerances, ensuring that each part meets your exact specifications.

Cost-Effective: Compared to traditional injection molding, vacuum casting is significantly more cost-effective for small to medium batch production, reducing tooling costs and lead times.

Material Flexibility: We offer a wide range of materials, including various types of polyurethane resins, that can mimic the properties of production-grade plastics, providing you with the flexibility to choose the best material for your application.

Short Lead Times: The vacuum casting process is relatively quick, allowing us to deliver parts in a shorter time frame compared to other manufacturing methods.

Surface Finish: The parts produced through vacuum casting have a high-quality surface finish, reducing the need for additional post-processing.

Our Vacuum Casting Process

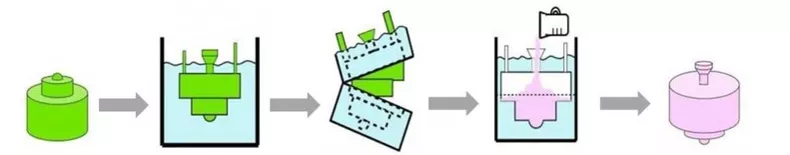

Step 1.Master Pattern Creation: We start with a high-quality master pattern, which can be created using 3D printing or other prototyping methods.

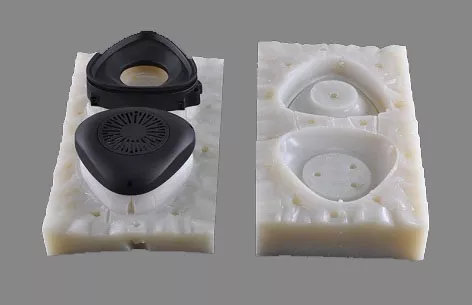

Step 2.Silicone Mold Making: A silicone mold is made from the master pattern, ensuring that all details are accurately captured.

Step 3.Casting Under Vacuum: The casting material is poured into the silicone mold under vacuum conditions to eliminate air bubbles and achieve a perfect finish.

Step 4.Post-Processing: After curing, the parts are removed from the mold and undergo any necessary post-processing, such as trimming, sanding, and painting.

Crafting excellence with vacuum casting. Produce high-quality parts with the finesse your project deserves. Interested in superior surface finishes and detail? Contact us for a quote and let's cast your success!