|

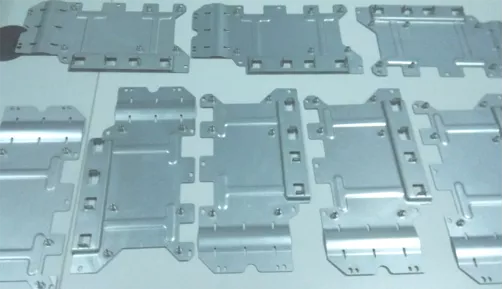

Stamping

|

This process involves using dies to shape and cut metal sheets under high pressure. Stamping is ideal for producing high volumes of identical parts with tight tolerances and complex geometries. |

|

Bending

|

Our state-of-the-art bending machines can create precise angles and curves, ensuring that each bend meets your exact specifications. Bending is crucial for creating structural components that require specific shapes and dimensions. |

Why Choose Our Sheet Metal Fabrication?

|

Precision and Consistency: Our advanced machinery and skilled technicians ensure that each piece is manufactured to precise specifications, with high repeatability and consistency.

Strength and Durability: Sheet metal components are known for their strength and durability, making them ideal for applications that require robust and long-lasting solutions.

Cost-Effective: Sheet metal fabrication is a cost-effective solution for both small and large-scale production runs, offering significant savings compared to other manufacturing methods.

Design Flexibility: The process allows for a wide range of design possibilities, enabling the creation of complex shapes and structures that meet your specific requirements.

Quick Turnaround: Our efficient processes and streamlined workflows ensure quick turnaround times, allowing you to receive your components faster without compromising on quality. |

|