| Consumer Goods | Automotive | Medical Devices | Electronics |

|

|

|

|

Why Choose Our Injection Mold?

High Precision and Consistency: Injection molding allows for the production of parts with extremely tight tolerances, ensuring that each part is identical to the next.

Efficiency and Scalability: The process is highly efficient for large-scale production, reducing unit costs as the volume increases.

Material Flexibility: A wide range of plastic materials can be used, allowing for parts with varying properties such as strength, flexibility, and durability.

Complex Gometries: Injection molding can produce parts with complex shapes and intricate details, which would be difficult or impossible to achieve with other manufacturing methods.

Surface Finish: The process can achieve high-quality surface finishes, reducing the need for secondary operations.

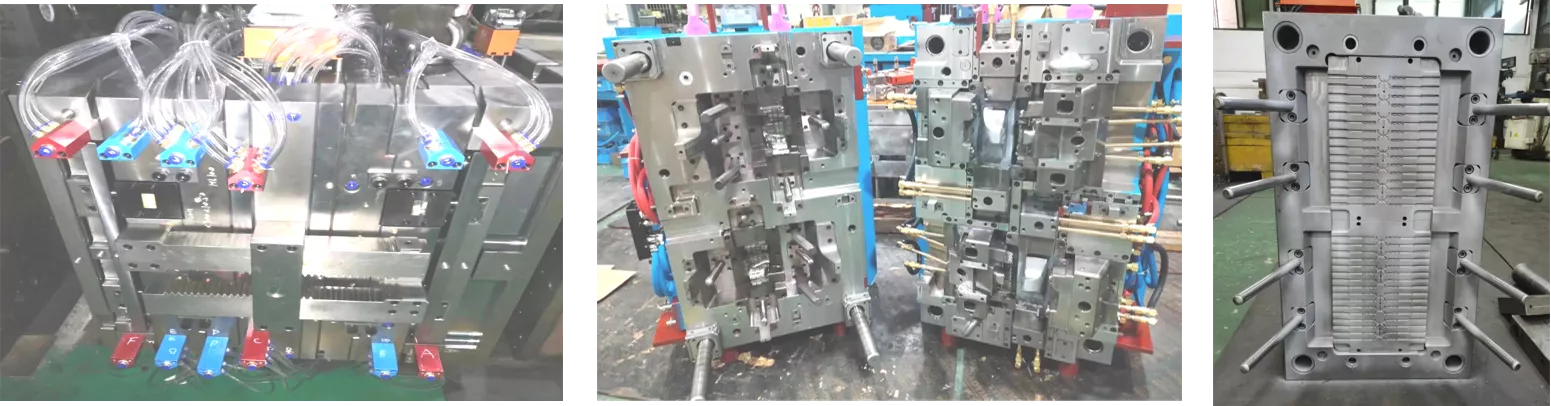

Our Injection Molding Process

Step1: Design and Engineering: Our experienced team works with you to design molds that meet your specific requirements, ensuring optimal functionality and efficiency.

Step2: Material Selection: We offer a wide range of high-quality plastic materials to match the specific needs of your project.

Step3: Mold Manufacturing: Using advanced CNC machines and other precision tools, we manufacture molds with high accuracy and durability.

Step4: Quality Control: Rigorous quality control measures ensure that each mold and part meets the highest standards.

Step5: Post-Processing: We provide a range of post-processing services, including painting, assembly, and packaging, to deliver finished products ready for use.

Mold success with our high-quality injection molding services. Reach out for a quote and produce with excellence.